In the era of industrial development, injection mold is the key root of automobile mould manufacturers, and it is also an indispensable and important process. Its processing quality is not only related to the excellent performance of plastic products, but also has a very direct relationship with the production cost of the enterprise. Therefore, in order to further improve the use efficiency of the mold and reduce the cost of plastic products, let's talk about how to improve the service life of the injection mold.

Different types of plastics require different temperatures for molding, and the shrinkage rates of plastics are also different. Therefore, different working conditions have different effects on the service life of plastic molds.

Therefore, under the premise of satisfying the use performance and product quality, plastic raw materials with good process performance should be used to process finished products, which is beneficial to the molding of products and the improvement of the life of automobile moulds.

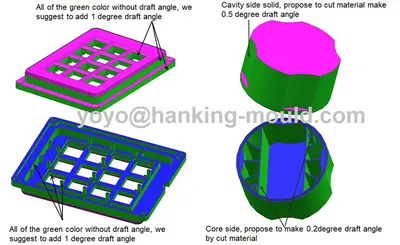

Cavity and core are the main molding parts of injection molded products. Are the strength and rigidity of different structural forms of cavities different, as well as the convenience of maintenance and replacement of wearing parts?

Therefore, from the perspective of the service life of automobile injection molds, the use of structural forms with better strength and rigidity and easy maintenance can prolong the service life of automobile moulds.

Automobile models are usually complex and have high requirements for precision and surface roughness. The choice of automobile mould materials will affect mold quality and service quality.

Whether the use and maintenance of the injection mold is correct is also a major factor affecting the service life of the mold. The automobile mould is properly debugged, the parameters of the injection molding machine meet the design requirements in production, and the planned regular maintenance of the automobile mould can improve the mold service life to a certain extent.

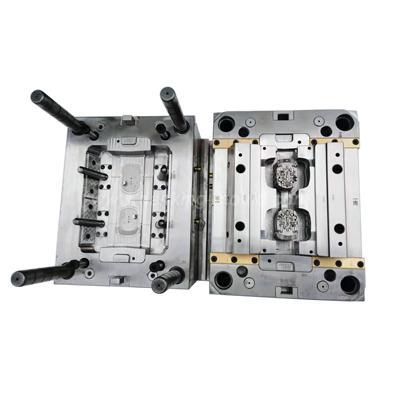

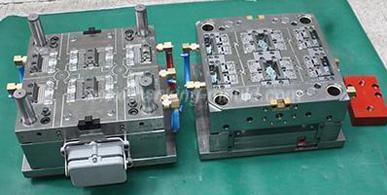

HanKing Mold designs and manufactures plastic injection molds in China, provides large factories for our global customers, and also provides customers with injection molding production services, including secondary processing and assembly, our global customers are from the United States, Germany, Switzerland, France, Italy, Austria, Israel, etc.

The company's business philosophy is "customer first, quality first", and it is a trustworthy injection mold manufacturing company. Welcome to consult.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.